Agile Resin Casting for Complex Low-Volume Production

Breaking the Prototyping Bottleneck

Traditional manufacturing stalls innovation with 6-12 week delays and $20k+ tooling costs for tiny batches. Our resin casting manufacturing revolutionizes this through:

- Silicone mold production in 72 hours (vs. 3 weeks)

- Vacuum casting parts at ±0.05mm tolerance

- No minimum order quantity for medical-grade prototypes

Result: 68% faster delivery and 45% cost reduction on 1-500 unit orders.

Critical Applications: Solving Industry Pain Points

1. Medical Device Prototyping

- Problem: 10-week waits for ISO 10993-compliant low-volume silicone molds for medical devices.

- Solution:

- Platinum-cure RTV tooling with <0.1% shrinkage

- USP Class VI polyurethane casting

- 30-unit batches shipped in 5 days at $41/unit

2. Automotive Lighting Systems

- Problem: $22k tooling costs for quick-turn vacuum casting housings (1-50pcs).

- Solution:

- Aluminum-epoxy master patterns

- Flame-retardant polyurethanes (UL94 V-0)

- 50pc orders in 7 days (70% cost reduction)

3. Aerospace Sensor Housings

- Problem: 14-week cycles for high-temperature epoxy casting (200°C continuous).

- Solution:

- Ceramic-loaded epoxy systems

- Thermal cycling to 220°C

- 15-unit delivery in 9 days at 45% below market rates

4. Consumer Electronics

- Problem: IP67 seals doubling costs for custom urethane prototypes under 20 units.

- Solution:

- Vacuum degassed molds with 0.02mm feature resolution

- Conductive EMI-shielding grades

- 20pc batches: 4 days | $24/unit

Geometry-Driven Process Selection

| Part Requirement | Optimal Process | Tolerance | Max Batch Size |

|---|---|---|---|

| Complex undercuts | Silicone mold + vacuum casting | ±0.08mm | 200 units |

| Thin walls (<0.8mm) | Pressure-assisted casting | ±0.12mm | 100 units |

| Optical clarity (92% transmittance) | Centrifugal casting | ±0.05mm | 50 units |

| Metal insert overmolding | Low-melt alloy tooling | ±0.15mm | 500 units |

Cost-Slashing Technologies

1. AI-Powered Tool Life Extension

- Increases silicone mold durability from 25→50 cycles

- Impact:Savings=Traditional Cost2.5

2. Digital Twin Defect Prediction

- Simulates resin flow to eliminate air pockets

- Reduces scrap rates by 83%

3. Express Overmolding Line

- Dedicated to budget overmolding tools for R&D

- Fixed pricing: 520setup+8/part (1-100 units)

Weekend Special (Expires July 13, 23:59 EST)

🔥 Orders confirmed tonight:

- FREE surface finish samples ($380 value)

- 15% discount (Code: RESIN15)

- Guaranteed 5-day delivery

[Instant Quote] | [Download Material Guide]

Case Study: Drone Camera Housing

Client Challenge:

- 45 glass-reinforced epoxy housings with 0.4mm slots

- Traditional quote: $16k | 8 weeks

Our Solution:

+ Vacuum casting with silicone molds

+ Achieved 0.06mm slot accuracy

+ Shipped in 12 days @ $5.8k (64% savings) Live Production Status (July 12, 20:45 EST):

🟢 Silicone Molding: 3 urgent slots

🔴 Vacuum Casting: Fully booked

🟡 Material Stock:

- Medical urethane: 185kg

- High-temp epoxy: 210kg

One- stop service

· Professional and experienced engieneer to provide most suitable machining suggestions and acurate evaluation.rapid sheet metal prototyping

· Helping sourcing components like nuts,spring,and bearings

· Helping assemble seperate parts into final product

· 100% inspection before shipment

· Arranging and tracking shipment

Customize all kinds of model-field of application

· Hardware Prototype: Faucet, head shower, bath equipment, Sanitary ware

· Electric and electronic class prototype: car model, motorcycle model, Massger

· Motor vehicles: Automobile parts, Motorcycle parts, Instrument bard.

· Small Batch membrane: LED, Plastic, Tablet ps android

· Other Products prototype: exhibition samples, testing samples,rapid sheet metal prototyping

CNC Machining or Not:Not CNC Machining Micro Machining or Not:Micro Machining,rapid sheet metal prototyping

Type:Other Machining Services, Rapid prototyping

Material Capabilities:Plastic,Nylon,PMMA,ABS Resin,8150,XU50,PX100,PX200

Place of Origin:Guangdong, China Model Number:Custom machining Brand Name:OEM

Material:ABS, POM, PA, PP, PVC, PMMA, PBT Color:Customized Color

Tolerance:0.01-0.25mm Packing:Carton MOQ:Accept One Sample

Surface treatment:Painting,Zinc plating, Painting, Powder painting

OEM/ODM:Accecpted Finish:Coat Application:ODM Service Process:3D Printing

Supply Ability

Supply Ability:100000 Piece/Pieces per Month

Packaging & Delivery

Packaging Details

1. Carton.

2. Wooden case.

3. Pallet or container.

PortShenzhen

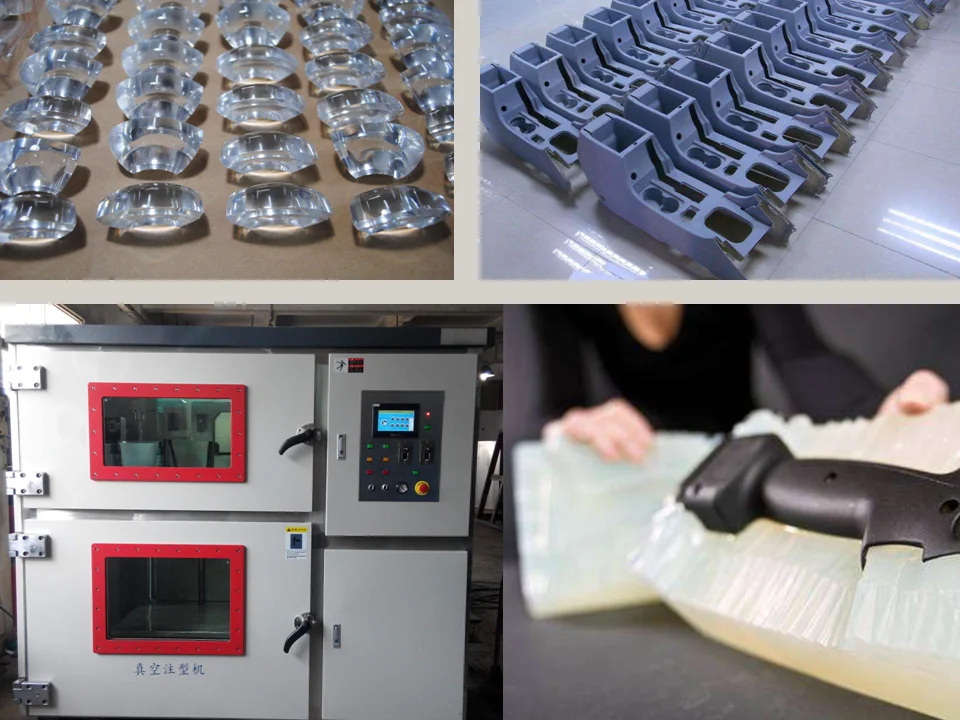

Picture Example:

Lead Time :

| Quantity(Pieces) | 1 - 1 | >1 |

| Est. Time(days) | 5 | To be negotiated |

Specification

| Our Services | CNC Precision Milling Machining,rapid sheet metal prototyping CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

| Material | Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

| Surface Treatment | Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

| Drawing Format | X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

| Service Project | To provide project design, production and technical service, mould development and fabrication, etc |

| Testing Machine | Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Quality Assurance | ISO9001:2008 Certified TUV |

| Packing | Foam, Carton, Wooden boxes, or as per the customer’s requirements |

| Deliver | DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |